Our commitment to do things differently has seen a 19% reduction in our carbon emissions this year.

Last year, we developed our plan for achieving net-zero carbon emissions by 2050, as set out in our sustainability strategy.

Known as our Carbon Emissions Reduction Plan, it is a robust carbon and financial model that maps our emissions reduction trajectory while considering business growth and the cost of transition to net zero.

GM Engagement and Sustainability Phil de Joux says by implementing this plan across the business, we are proud of the overall reduction in emissions, most notably in our most significant emissions area, fuel.

“The reduction is a result of several different factors, most notably new lower emission large plant and different practices implemented in the container terminal.”

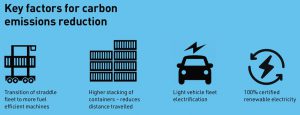

This has included prioritising the use of our more fuel-efficient diesel-electric Noell straddles, as well as the gradual decommissioning of our older less fuel-efficient straddles.

“We have preferentially used our newer straddles over the past year because they are also capable of stacking higher,” says Phil.

“This higher stacking also helps because it reduces the distance travelled by the machines – saving fuel in the process.”

Another factor in the reduction of fuel use is that shipping was slightly down which meant our marine fleet (Tugs / Pilot vessel) made fewer vessel movements during the year.

“While this is partly due to shipping disruptions caused by COVID-19, this will be an area of analysis moving forward,” says Phil.

We also made the commitment to use a fully certified renewable electricity source across the business, meaning our emissions from electricity for FY2021 were zero.

“This is particularly important for us into the future as the proportion of refrigerated containers to non-refrigerated is growing, especially with Lyttelton’s growing importance as a transshipment port,” says Phil.

Our transition to an electric light vehicle fleet has also represented another immediately accessible reduction opportunity.

This year has also established a benchmark for our waste emissions, as we are now working with a single supplier across the business which we know will provide excellent data to reduce our waste moving forward.

But our work does not stop here.

We know our large plant and equipment presents a larger challenge. Our straddle fleet, which has seen improvement this year and is already mostly diesel-electric, still forms a large part of our emissions profile.

“Right now, there are no viable zero emissions solutions, but biodiesel, hydrogen and battery electric options all show promise,” says Phil.

“We are not alone in the challenges we face, and collaboration has been a key factor in our success.”

As part of the Sustainable Business Council, we are engaging with energy suppliers, staying up to date on global developments and learning from other companies’ transition journeys, particularly those dealing with large plant.

We are also working in partnership with other CCHL-owned companies.

“We know our target is ambitious, but we believe this year is a testament that we can make steps towards reducing our carbon emissions while growing sustainably and playing our part in the global effort to combat climate change,” says Phil.